Equipment and Material Compatibility Assessment

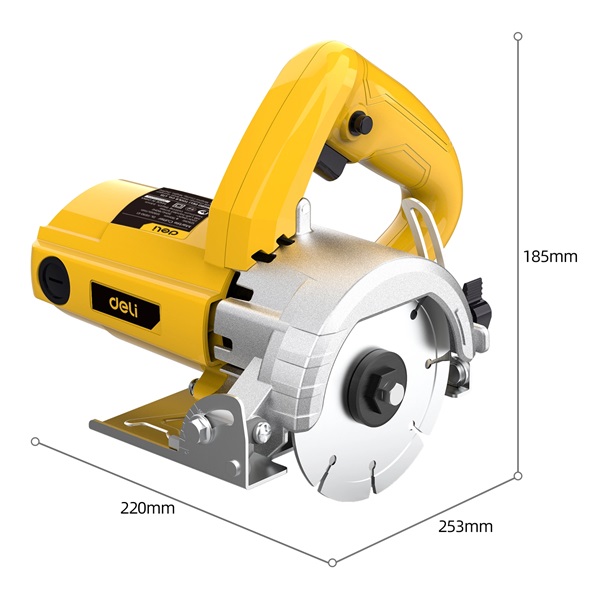

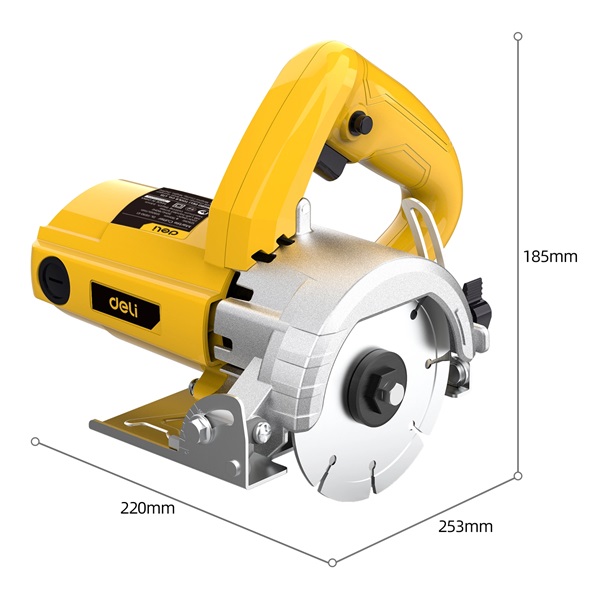

A marble cutter is a precision tool designed to cut through natural stone, engineered stone, and other hard materials with accuracy and efficiency. Assessing equipment and material compatibility is the first step in achieving optimal results. Different types of marble, granite, and ceramic materials require blades with specific properties, such as diamond-coated edges or reinforced steel structures, to ensure clean cuts without chipping. The motor power, cutting depth, and blade speed must also match the material hardness and thickness. Understanding the interaction between the marble cutter and the chosen material allows operators to avoid unnecessary wear on the equipment and achieve high-quality finishes. Brands like Deli Tools ensure that their marble cutters are engineered with versatile adaptability, supporting a wide range of material types and thicknesses to meet professional and DIY demands.

Precision and Efficiency in Cutting

Precision is a critical factor when using a marble cutter. Accurate measurement, stable operation, and correct blade selection ensure straight and smooth cuts, which are essential for aesthetic and structural applications. Efficiency comes from combining high-performance motors with durable cutting discs that maintain speed under continuous operation. A well-designed marble cutter minimizes vibrations, allowing operators to follow precise lines while reducing material wastage. Deli Tools’ marble cutters integrate ergonomic designs and reliable motor systems, providing both control and endurance during extended cutting tasks. Efficiency is further enhanced when tools are compatible with adjustable cutting guides, allowing operators to execute repeated cuts with consistent quality.

Safety Measures and Operational Best Practices

Operating a marble cutter requires adherence to safety measures due to the high-speed rotation of blades and potential flying debris. Personal protective equipment, including safety goggles, gloves, dust masks, and hearing protection, is essential to prevent injury. Securing the workpiece and maintaining a clean workspace reduces the risk of accidents and ensures uninterrupted operation. Using water-cooled systems or wet cutting techniques minimizes dust generation and heat buildup, extending blade life while maintaining a safe working environment. Following operational best practices, such as maintaining a firm grip and avoiding excessive force, reduces the likelihood of blade breakage and enhances control. Marble cutters from Deli Tools incorporate safety features like protective guards and stable bases, which support safer operation in both professional and domestic environments.

Versatility for Various Applications

Marble cutters are not limited to cutting large slabs; they are versatile tools capable of handling intricate shapes, bevel cuts, and detailed edging. This versatility allows them to serve multiple industries, including construction, interior design, sculpture, and DIY home improvement projects. Operators can switch between dry and wet cutting techniques, adjust cutting angles, and select appropriate blade types to achieve specific finishes. Deli Tools provides marble cutters with multi-functional capabilities, allowing users to transition seamlessly between different tasks and materials. Whether cutting countertops, flooring tiles, or decorative stone elements, these cutters meet diverse application requirements with precision and efficiency.

Maintenance and Longevity Considerations

Maintaining a marble cutter ensures consistent performance and extends the tool's operational life. Regular inspection of blades for wear, cleaning of the motor and ventilation areas, and checking electrical connections prevent operational issues. Storing the cutter in a dry and secure environment protects sensitive components from corrosion or damage. Proper maintenance not only improves performance but also enhances safety by reducing unexpected malfunctions during use. High-quality marble cutters from Deli Tools are designed for durability, with components that withstand rigorous cutting tasks and facilitate easy maintenance, providing reliable performance for long-term applications.

EN

EN

jp

jp  ko

ko  fr

fr  de

de  es

es  it

it  ru

ru  pt

pt  ar

ar  vi

vi  th

th  hi

hi  pl

pl  id

id  el

el